Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Car wheel parts manufacturer

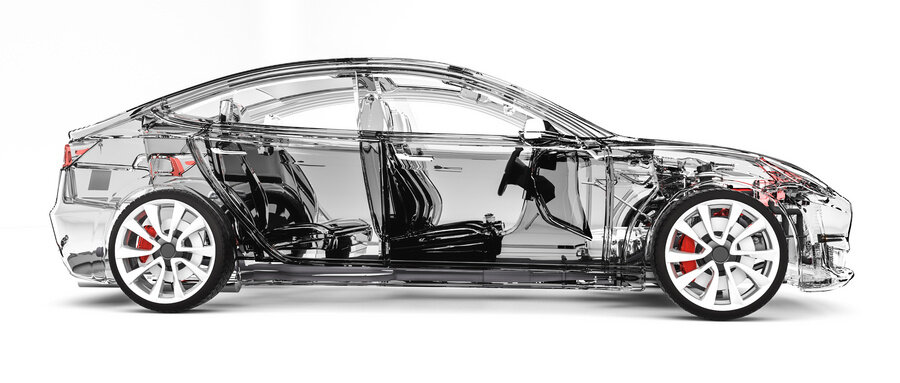

Car wheel parts manufacturers are companies that specialize in designing and producing parts that are used in the construction of car wheels. These parts include rims, spokes, hubs, bearings, and other components that are essential for the proper functioning of a wheel. The manufacturers work with automotive companies, aftermarket suppliers, and other businesses to ensure that they produce high-quality parts that meet the strict standards of the automotive industry.

History and Evolution of Car Wheel Parts Manufacturing

The history of car wheel parts manufacturing can be traced back to the early days of the automobile industry. In the early 1900s, car manufacturers began producing their own wheels and wheel parts, but as the industry grew, the demand for specialized parts increased. This led to the emergence of specialized wheel parts manufacturers who could produce high-quality parts at a lower cost than the car manufacturers.

Over time, the manufacturing process has evolved, with new technologies and materials being introduced to improve the performance and durability of car wheels. Today, modern wheel parts manufacturers use advanced computer-aided design (CAD) software to create highly precise and complex parts. They also use advanced materials such as carbon fiber, titanium, and aluminum to create lightweight, yet strong and durable components.

The Role of Car Wheel Parts Manufacturers

Car wheel parts manufacturers play a critical role in the automotive industry. Their products are essential for the proper functioning of a vehicle, and they must meet strict safety and performance standards. The manufacturers work closely with car companies and other businesses to ensure that their parts meet the necessary specifications and are compatible with a range of vehicles.

The process of manufacturing car wheel parts typically involves several steps. First, the manufacturer creates a design for the part using CAD software. Once the design is finalized, the manufacturer uses specialized equipment to produce a prototype of the part. This prototype is then tested and refined until it meets the necessary standards.

Once the design has been finalized and the part has been tested, the manufacturer begins the process of mass production. This involves using specialized machinery to create multiple copies of the part. The parts are then inspected to ensure that they meet the necessary specifications before being packaged and shipped to the customer.

Types of Car Wheel Parts

Car wheel parts manufacturers produce a wide range of components that are used in the construction of car wheels. Some of the most common parts include:

Rims: The rim is the outermost part of the wheel, which holds the tire in place.

Spokes: The spokes are the thin rods that connect the rim to the hub.

Hubs: The hub is the central part of the wheel that connects it to the car's axle.

Bearings: Bearings are small components that reduce friction between the hub and the axle.

Lug Nuts: Lug nuts are used to secure the wheel to the car's hub.

Materials Used in Car Wheel Parts Manufacturing

Car wheel parts can be made from a range of materials, depending on the specific requirements of the part. Some of the most common materials used in car wheel parts manufacturing include:

Steel: Steel is a durable and cost-effective material that is commonly used in the production of car wheel parts.

Aluminum: Aluminum is a lightweight material that is commonly used in high-performance car wheels.

Carbon Fiber: Carbon fiber is an extremely lightweight and strong material that is often used in high-performance racing wheels.

Titanium: Titanium is a strong and lightweight metal that is commonly used in the aerospace industry. It is also used in the production of high-performance car wheels.

Quality Control in Car Wheel Parts Manufacturing

Quality control is an essential aspect of car wheel parts manufacturing. To ensure that their parts meet the necessary standards, manufacturers use a range of testing and inspection techniques. These techniques include:

Non-Destructive Testing:

Non-destructive testing (NDT) is a technique that allows manufacturers to inspect the quality of a part without damaging or altering it. This can include techniques such as X-rays, ultrasonic testing, and magnetic particle inspection.

Dimensional Inspection:

Dimensional inspection involves measuring the physical dimensions of a part to ensure that it meets the necessary specifications. This can include using precision measuring tools such as micrometers, calipers, and gauges.

Material Testing:

Material testing involves testing the physical properties of the materials used in the production of car wheel parts. This can include tensile strength testing, hardness testing, and impact testing.

Durability Testing:

Durability testing involves subjecting a part to a range of stresses and strains to determine how it will perform over time. This can include testing for fatigue, corrosion resistance, and wear resistance.

Quality control is an ongoing process that takes place throughout the entire manufacturing process. Manufacturers also work closely with customers and other businesses to ensure that their parts meet the necessary standards and are compatible with a range of vehicles.

Market Overview

The car wheel parts manufacturing market is highly competitive, with numerous companies vying for market share. Some of the largest manufacturers in the industry include BBS, Enkei, Ronal, and OZ Racing. These companies produce a range of high-performance wheels and wheel parts for both OEM and aftermarket applications.

The market for car wheel parts is expected to continue to grow in the coming years, driven by increasing demand for lightweight and high-performance wheels. Manufacturers are also investing in new technologies and materials to improve the performance and durability of their products.

Car wheel parts manufacturers play a critical role in the automotive industry, producing high-quality parts that are essential for the proper functioning of a vehicle. These manufacturers use advanced technologies and materials to create lightweight, strong, and durable parts that meet strict safety and performance standards.

Quality control is an essential aspect of car wheel parts manufacturing, with manufacturers using a range of testing and inspection techniques to ensure that their parts meet the necessary specifications. The market for car wheel parts is highly competitive, with numerous companies vying for market share by producing high-performance wheels and wheel parts for both OEM and aftermarket applications.

China car wheel parts manufacturer

China has become a hub for manufacturing and exporting car wheel parts, with a large number of manufacturers operating in this space. The country's competitive pricing and high-quality production have made it a preferred destination for sourcing car wheel parts by automotive companies worldwide.

China car wheel parts manufacturers offer a wide range of products such as aluminum alloy wheels, steel wheels, hubcaps, and wheel accessories. These products are designed and manufactured to meet the standards and requirements of different automobile brands and models.

The manufacturing process of car wheel parts involves several stages such as design, casting, machining, painting, and testing. China car wheel parts manufacturers have invested heavily in advanced technologies and production processes to ensure the quality and durability of their products.

One of the significant advantages of sourcing car wheel parts from China is the cost-effectiveness. The country's low labor costs and government subsidies have made it possible for manufacturers to offer their products at competitive prices. This has enabled many automotive companies worldwide to reduce their production costs and improve their profit margins.

In addition to cost-effectiveness, China car wheel parts manufacturers have also focused on improving their quality standards. They have implemented various quality control measures and obtained international certifications such as ISO 9001 to ensure that their products meet the required quality standards.

China car wheel parts manufacturers have also expanded their production capacity to cater to the growing demand for their products. They have established manufacturing facilities in different parts of the country and have also invested in advanced machinery and equipment to improve their production efficiency.

The country's export-oriented economy has also played a significant role in the growth of its car wheel parts manufacturing industry. China car wheel parts manufacturers have been able to leverage the country's extensive logistics network and trade agreements to export their products to different parts of the world.

Custom Flow Forming Alloy wheel - 2022 New FF001

The material of a wheel has a very important influence on the overall weight and appearance of wheels. According to the different materials, it can be divided into steel, aluminum alloy and composite material. The composite material refers to carbon fiber; aluminum alloy is lightweight, strong and easy to process; and steel is durable but heavy. The appearance of aluminum alloy wheels is more beautiful than that of steel wheels, but its ability to release heat is less than that of steel wheels.