Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

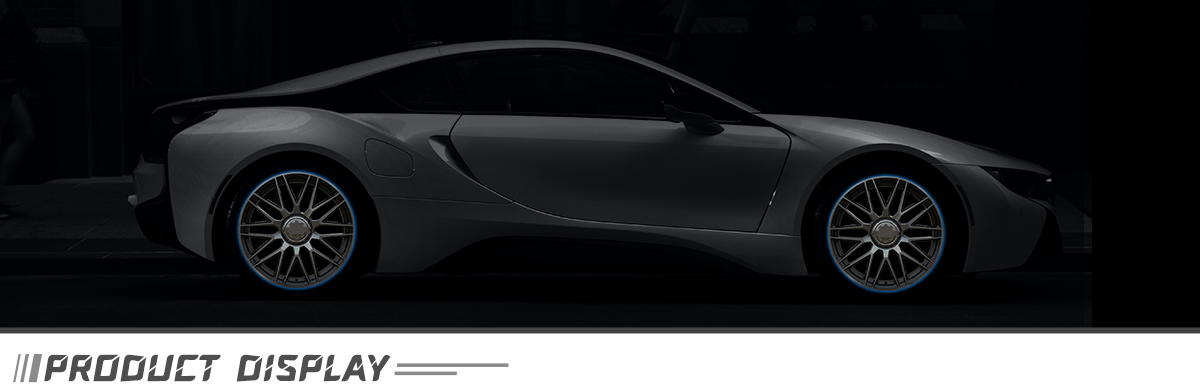

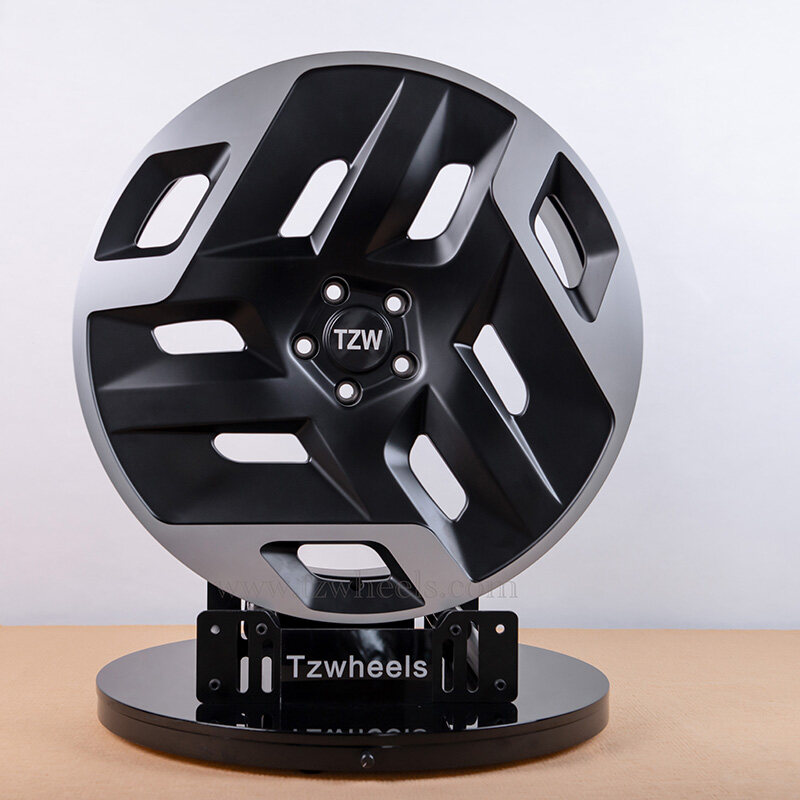

Aluminum Replica Car Alloy Wheels for LAND ROVER

Features of Aluminum Replica Car Alloy Wheels for LAND ROVER,These alloy wheels are manufactured by a leading alloy wheel manufacturer utilizing the highest-quality materials, to provide outstanding performance and durability.

FITMENT SIZE ET PCD CB

LAND ROVER 1880 35 5*120 72.6

LAND ROVER 2090 45 5*108 63.4

LAND ROVER 2195 45 5*108 63.4

LAND ROVER 2195 45 5*120 72.6

LAND ROVER 2295 49 5*120 72.6

LAND ROVER 2295 45 5*120 72.6

LAND ROVER 2295 45 5*108 63.4

The material of the vehicle wheel mainly refers to steel materials, aluminum alloys and composite materials. The composite material mainly refers to carbon fiber. The replacement of the hub is mainly due to its high cost, it is not easy to promote, the manufacturing process is complex with high technical difficulty. Common household cars use aluminum alloy wheels because they have better adaptability for lightweight cars compared to steel-made wheels, and because their appearance is more beautiful than that of steel wheels. They also release more heat so aluminum alloy has a wide range of applications.

Features of Aluminum Replica Car Alloy Wheels for LAND ROVER

These alloy wheels are manufactured by a leading alloy wheel manufacturer utilizing the highest-quality materials, to provide outstanding performance and durability.

Advantages

The manufacturing process utilizes advanced techniques and cutting-edge technology to ensure that every wheel is precisely crafted to meet the specific needs of each vehicle make and model. The result is a superior quality product that not only looks great but also delivers optimal performance, reliability, and longevity.

FAQ

Q: How can I solve this problem if I did not receive the product?

A: We will have a corresponding bill of lading for each shipment, and there is no problem of not receiving the goods.

Q: How about your after-sales service?

A: 3-year warranty for normal use, free replacement if there is a problem.

Q: Is it possible to order samples?

A: Yes.

What is the aluminum alloy modified wheels?

Cast aluminum alloy wheels

How are cast aluminum alloy wheels produced? Simply put, it is to heat the cast metal material to a liquid state, then pour the high-temperature liquid metal into different casting molds, and then finish the final product through grinding, polishing, etc.

Casting is generally divided into two types, one is gravity casting and the other is low pressure casting. Gravity casting is a relatively primitive casting process, which relies on the gravity of aluminum water to pour into the mold, and then fills all corners of the mold through its pressure. The method of this process is relatively simple and the cost is lower, but the product quality is not controllable, and it is prone to defects. It has been almost completely replaced by low pressure casting in the automotive wheel manufacturing industry.

Forged alloy wheels

Forging is a more advanced process than casting. Because the finished product is expensive, it will not be used in general family cars or even mid-to-high-end cars. Forging is a manufacturing process in which a solid aluminum alloy blank is extruded and deformed into a certain shape, strength and size by applying huge pressure to the solid aluminum alloy billet through a forging press. The forged blank is then finished to become the final product, which is the same as casting. Through the adjustment of a series of complex processes such as reasonable forging ratio and temperature control, forged parts with different strengths and properties can be forged.

Forged aluminum alloy wheels are more suitable for cars in terms of strength and lightweight. However, the cost of the current forging process is extremely high and can only be used in the high-end market. Whether it is a vehicle manufacturer or a refit manufacturer, forged wheels are absolutely high-end goods. The price of a forged aluminum alloy wheel may be several times higher than that of a cast aluminum alloy wheel, and even some forged wheels with extremely complex shapes and processes are expensive. It is more than ten times higher, so it is impossible to popularize in a short time.

MAT spinning technology wheels

Cast wheels are not strong enough, and forged wheels are too expensive. What if you want the weight and strength of the wheel to be guaranteed, while keeping costs under control? MAT spinning technology is a new technology born to reconcile the advantages and disadvantages of casting and forging processes.

MAT spinning wheel hub is actually a kind of cast aluminum alloy wheel hub, but the difference is that the casted wheel hub blank will be processed by special equipment for spinning process on its stress. The molecular arrangement inside the metal will change at the treated position, showing a fibrous shape with a higher density than the cast hub, which changes the mechanics of the metal and improves its strength. This allows the wheel to be made lighter and thinner, and at its lightest weight can be 15% lower than a cast aluminum alloy wheel, yet be as strong as a forged wheel.