Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

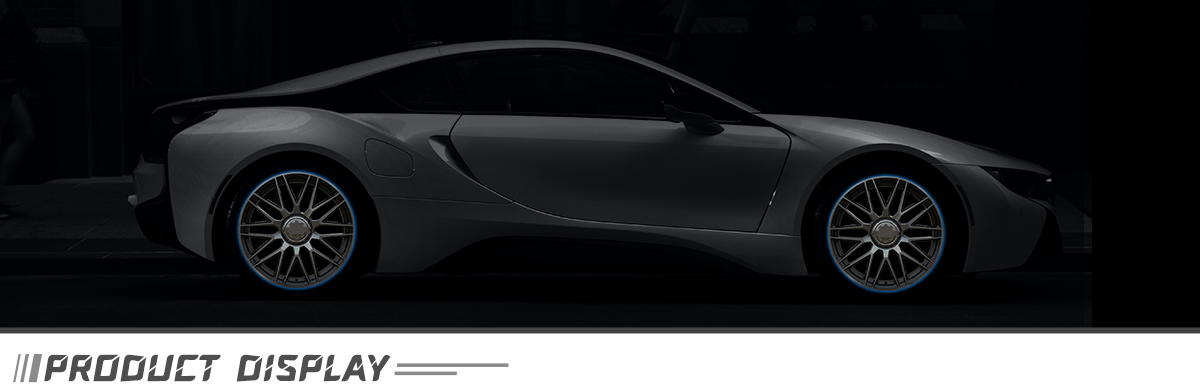

Matte Black Alloy wheel - BBS 2020 New 588

The BBS 2020 New 588 is a very stylish and modern alloy wheel, designed with a terrific chrome finish. It would look great on any vehicle in a sleek silver with dark rims look. This lightweight wheel can be used on anything from luxury cars to sports cars, as they are made to be strong while also keeping their weight down.

FITMENT SIZE ET PCD CB

BBS 1885 28-40 5*100-120 73.1

BBS 1985 30-40 5*100-120 73.1

BBS 1995 30-40 5*100-120 73.1

BBS 2085 30-45 5*100-120 73.1

BBS 2090 35-45 5*100-120 73.1

BBS 2095 30-45 5*100-120 73.1

BBS 2010 35-45 5*100-120 73.1

The BBS 2020 New 588 is a very stylish and modern alloy wheel, designed with a terrific chrome finish. It would look great on any vehicle in a sleek silver with dark rims look. This lightweight wheel can be used on anything from luxury cars to sports cars, as they are made to be strong while also keeping their weight down.

Features

The powder-coated wheels have a polished finish that enhances the look and feel of the plastic. It forms an oil film with excellent self-lubricating properties and has excellent wear resistance.

Benefits

Steel rims are easy to change. Once you have the materials, you can start designing right away.

Supply Ability

・Monthly production capacity is about 100,000 units.

・Our production MOQ is 60 pieces per item, but some popular items start at 40 pieces per item.

・If your order is less than 20 pieces, each piece is only available if it is in stock.

・Upon request, we will send you a new stock list (castings and forgings).

・We maintain a large inventory that is regularly updated. There is no minimum order quantity for orders from our current inventory, nor is there one in our product catalog.

・Samples are available if stock is available.

Packaging & Delivery

· The manufacturing cycle for cast wheels takes 25–45 days, depending on the technical requirements and peak season.

· Forged wheel production normally takes 15 days.

PS: Our company can provide sea transportation and rail transportation. Land transportation. It is very convenient for you to choose the transportation you need. Shipping methods for all channels by air. Sea freight takes the longest time but is the cheapest, air freight has the best timeliness but is the most expensive.

Our Service

·Can provide one-to-one product customization service.

·Can help customers go online and recommend hot-selling wheel products according to the customer market.

·Can provide door-to-door sea, land and air freight services.

Do I need to replace the iron wheels with aluminum alloys?

It would be better to replace the iron wheels of the original car with aluminum alloy wheels.

There are many names for car wheels, such as hubs, rims, rims, wheel wheels, and tire bells. According to the academic world, the hub refers to the rotating part of the wheel core connected by the inner profile of the tire through the column, that is, the metal part that supports the center of the tire and is mounted on the shaft. Its main function is to support the tire and transmit power.

There are two common types of wheels, one is steel or iron wheels, and other is aluminum alloy wheels. Steel wheels are generally common in low-end cars, such as domestic low-priced vans, low-end joint venture small cars, mini cars, etc. For example, the models sold by Rena are steel wheels.

Advantages and disadvantages of steel wheels

Steel wheels appeared earlier than aluminum alloy wheels, because steel wheels have low manufacturing cost, low manufacturing difficulty, and good hardness and toughness, and the requirements for manufacturing equipment are not high.

Steel hubs are generally rolled and stamped into billets, which are then assembled by welding and other processes. Finally, after sanding and painting, it can be loaded into the car.

The advantage of steel wheels is that they are cheap. Compared with aluminum alloy wheels, steel wheels have natural advantages in terms of raw materials, equipment requirements or processing difficulties. Therefore, many low-priced cars will cut corners on the wheels in order to find ways to create profit points.

The advantage of steel wheels is that they are cheap, but there are naturally some disadvantages.

Because of the characteristics of the steel itself, the hardness is not particularly high. If it encounters a violent impact, such as a large pit and does not decelerate and rush forward directly, when the tire is dry-blasted, it is also easy to dry-deform the wheel, because the hardness is not enough. If the wheel hub is deformed, now the car vacuum has no inner tube, and the air pressure cannot be sealed, the wheel hub is considered useless, unless an expert pulls the wheel back a little bit.

In addition, the density of steel is relatively high, and the steel wheel hub of the same size will be about 1/3 of that of the aluminum alloy wheel hub. At the same time, due to the pursuit of cost, the shape of the steel wheel hub is really not high-grade, and it can only play a basic supporting role. Additional functions such as beauty and generosity will not be considered.

Advantages of aluminum alloy wheels

Compared with steel wheels, aluminum alloy wheels are taller.

There are many advantages of aluminum alloys, such as the lower density of aluminum alloys, and the lighter weight of the wheels. For example, aluminum alloys have higher hardness and can withstand more violent impacts. Generally, the steel wheel is deformed after a sudden impact, and the aluminum alloy wheel can basically bear it. For example, aluminum alloys are equipped on mid-to-high-end cars, which can make a better-looking shape. In addition to practicality, it can also play a role in being beautiful and elegant, and improving the appearance of the vehicle.