Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

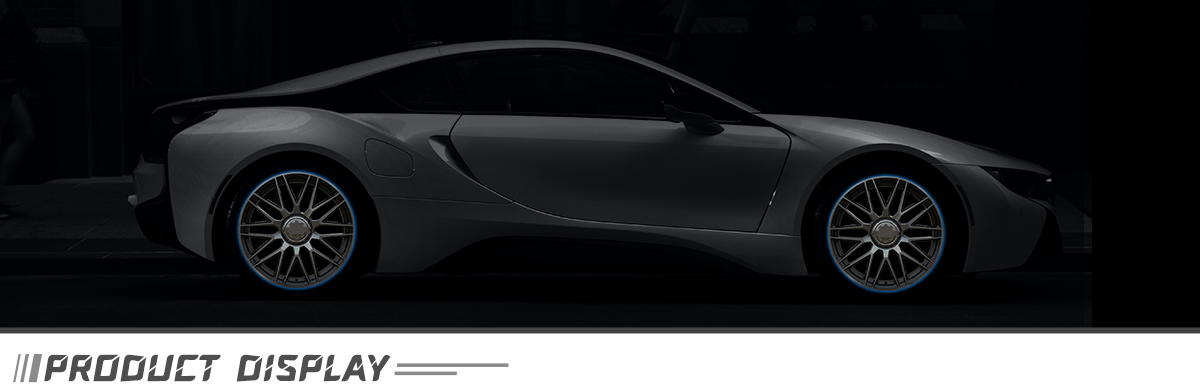

19/20 inch Replica Car alloy wheels for 2022 new AUDI A6

The Aluminum Hub Drive is a high-strength alloy wheel due to its light weight, strength, and heat dissipation. Aluminum wheels are generally lighter than steel wheels of similar strength, but less hard, so they will deform under heavy loads. Aluminum also has better shock absorption than steel at low speeds, but not at high speeds.

FITMENT SIZE ET PCD CB

AUDI A6 E-TRON 1985 25-35 5*112 66.45

AUDI A6 E-TRON 2090 25-35 5*112 66.45

The Aluminum Hub Drive is a high-strength alloy wheel due to its light weight, strength, and heat dissipation. Aluminum wheels are generally lighter than steel wheels of similar strength, but less hard, so they will deform under heavy loads. Aluminum also has better shock absorption than steel at low speeds, but not at high speeds.

“Not all Alloy Wheels Are Made Equal”

Features

Alloy Wheels are usually constructed from aluminum or an alloy of aluminum that contains high quantities of magnesium. The benefits of alloy wheels are the decreased mass and better heat management.

Benefits

Comparatively, alloy wheels are much lighter than other wheel options such as steel and carbon fiber. This lightness preserves fuel efficiency and accelerates performance while maximizing tread life.

Advantages

1. Full wheel protection, good performance on dry and wet roads, and greater resistance to corrosion than steel wheels.

2. Handling and appearance are significantly improved.

Restoration of the original appearance can be accomplished quite easily. Depending upon their age, one or both of the alloy wheels may require minor reconditioning prior to refinishing. This involves taking a few passes on a wire-brush wheel with a medium that frequently changes position as a result of the pressure of adjacent brush wheels. The wheels are often dyed after machining, but before polishing to make them appear as original equipment manufacturer parts.

Compared with steel car wheels, what are the advantages of aluminum alloy wheels?

1. Save fuel. On average, each aluminum alloy wheel is 2kg lighter than a steel wheel of the same size, and a car can save 10kg by using 5 wheels. According to Japanese experiments, the weight of a 5-seater car is reduced by 1kg, which saves about 20L of gasoline a year. The research report published by the American Society of Automotive Engineers pointed out that although aluminum alloy wheels are more expensive than ordinary steel wheels, when each car runs to 20,000 kilometers, the fuel cost saved will fully cover the cost.

2. Increase engine life. The engine load is negatively correlated with the life of the engine, the greater the load, the shorter the life. Because aluminum alloy wheels are lighter than steel wheels, engine life can be extended.

3. Good heat dissipation. The thermal conductivity of aluminum alloy is 3 times that of steel, and the heat dissipation effect is good. During long-distance high-speed driving, it can also keep the tires at an appropriate temperature, so that the brake drums and tires are not easy to age, increase the service life, and reduce the chance of a tire blowout.

4. High precision. The true circle accuracy of the aluminum alloy wheels is as high as 0.05mm, and the running balance is good, which is conducive to eliminating the phenomenon of steering wheel shaking.

5. Sturdy and durable. The strength of aluminum alloy wheels is higher than that of steel wheels in terms of impact resistance, tension resistance and thermal force. This is also one of the reasons why aluminum alloys play an important role in the defense industry and the aviation industry.

6. Beautiful. Due to the limitation of production, general steel wheels are monotonous and rigid in form and lack changes; aluminum alloy wheels have various designs, plus the gloss and color effect is good, thus improving the value and beauty of the car.