Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

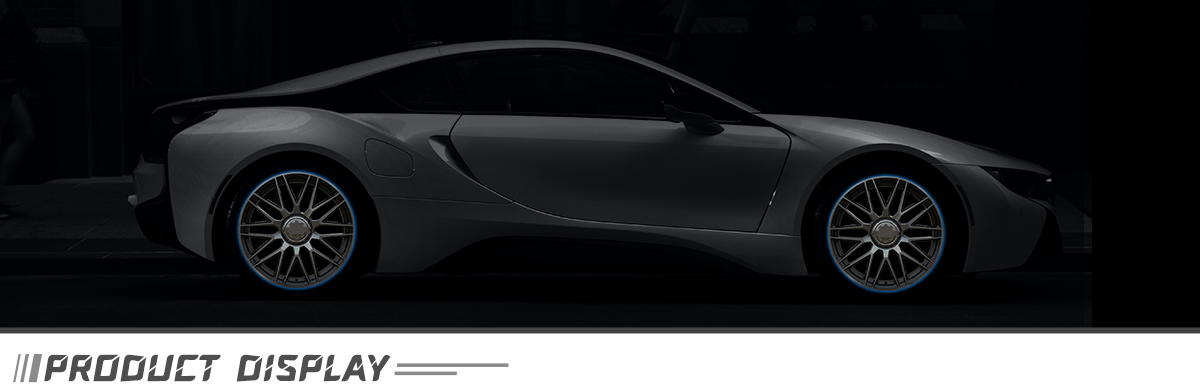

2020 New Method 4X4 Alloy wheel Code 208

2020 New Method 4X4 Alloy wheel Code 208 are made of lightweight and corrosion-resistant aluminum alloy, with unique 6-spoke design. With a larger diameter than stock, the wheels not only make your 4WD stand out from the crowd, but also enhance its stability and cornering performance in all road conditions.

FITMENT SIZE ET PCD CB

METHOD 1785 0 5/6*127-150 77.8-110

2020 New Method 4X4 Alloy wheel Code 208 are made of lightweight and corrosion-resistant aluminum alloy, with unique 6-spoke design. With a larger diameter than stock, the wheels not only make your 4WD stand out from the crowd, but also enhance its stability and cornering performance in all road conditions.

Features

Code 208 wheels are made of lightweight and corrosion-resistant aluminum alloy, with unique 6-spoke design.

Advantages

With a larger diameter than stock, the wheels not only make your 4WD stand out from the crowd, but also enhance its stability and cornering performance in all road conditions.

Benefits

This type of wheel will both improve the look of your vehicle as well as make it more comfortable to drive.

This wheel features a five-star stamp, which is more reliable and durable than ordinary four-wheel stamping wheels.

What are the advantages of aluminum alloy wheels compared to iron wheels?

Now there are some new models on the market, because the low-profile models are equipped with iron wheels. Although this kind of wheel can also be used for daily use, there is a certain gap between the controllability and aesthetics and the aluminum alloy wheel.

There are more and more wheel styles on the market, and many consumers have the idea of replacing iron wheels with aluminum alloy wheels.

Is this approach correct? What are the advantages of aluminum alloy wheels compared to iron wheels? How long does it take for a new car to be replaced with aluminum alloy wheels?

Cooling function

First of all, one of the great advantages of aluminum alloy wheels compared with iron wheels is heat dissipation. First of all, the heat transfer coefficient of aluminum alloy will be about three times larger than that of ordinary iron wheels.

As we all know, tires and wheels generate a lot of heat when the car is driving. If this heat accumulates on the wheels, it will even affect the performance of the brakes. Causes brake and wheel tire wear. Aluminum alloy wheels will quickly conduct this heat into the air, which undoubtedly increases the safety factor of the vehicle.

Lightweight

Secondly, the weight of the aluminum alloy wheel will be about two kilograms lighter than the iron wheel, so the four aluminum alloy tires will be about eight kilograms lighter than the iron tire.

To a large extent, it can contribute to the handling of the car, making it more flexible when turning or cornering. It can also reduce fuel consumption to a certain extent.

Beautiful

In addition, the aluminum alloy wheel is also more beautiful than the iron wheel, and the replacement of the wheel of the same size is allowed in the annual inspection.

What are the production methods of aluminum alloy wheels?

At present, the mainstream forming process of aluminum alloy automobile wheels is divided into forging and casting. Under the same conditions, the mechanical properties of forged aluminum alloy (6061 alloy) wheels are better than those of cast aluminum alloy (A356.2 alloy) wheels. Therefore, for wheels with the same structure and the same requirements, the aluminum alloy wheels of 6061 material made by forging process can be lighter than the cast wheels of A356.2 material. According to rough statistics, the weight difference is about 3~5%. Due to limitations, the current manufacturing cost of forged aluminum alloy wheels is much higher than that of cast aluminum alloy wheels.