Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

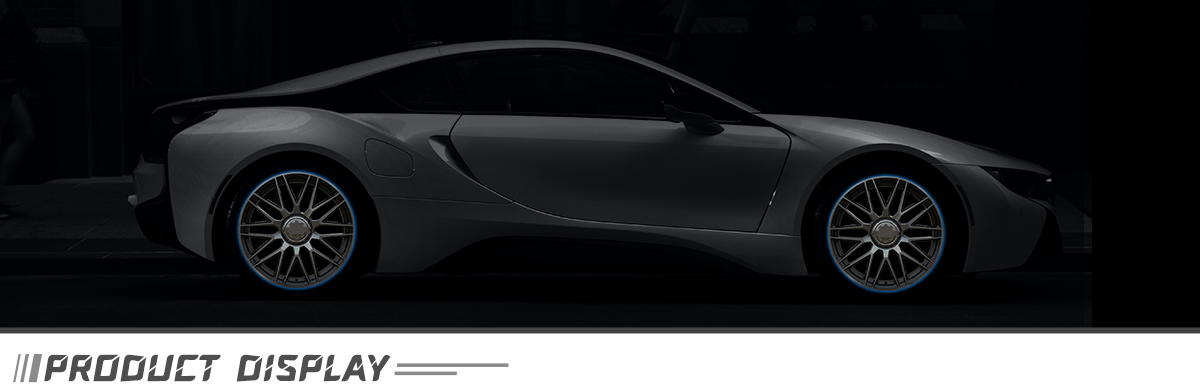

17*85 inch 4x4 alloy wheels - 2020 New Code 209

We use aluminum alloy wheels in our 4×4 vehicles to reduce weight and improve fuel consumption. The anti-theft effect is good. Alloy wheels are also easy to maintain, durable and light in weight, allowing you to use it for a long time.

FITMENT SIZE ET PCD CB

METHOD 1785 0 5*150/6*139.7 110.5

We use aluminum alloy wheels in our 4×4 vehicles to reduce weight and improve fuel consumption. The anti-theft effect is good. Alloy wheels are also easy to maintain, durable and light in weight, allowing you to use it for a long time.

Features

To meet the aesthetic needs of our customers, all the aluminum alloy wheels need to be polished.

Advantages

Light weight and high strength are the characteristics of aluminum alloy wheels. They are also corrosion and impact resistant, and they are wear resistant.

Benefits

They can withstand extreme temperatures and extend their service life for a long time. This makes them a very good option for people looking for high-quality vehicles.

Aluminum alloy wheels

Aluminum alloy wheels are also called aluminum rings or aluminum wheels. As the name suggests, they are wheels made of aluminum alloy with less density. Aluminum alloy wheels have the advantages of light weight, diverse shapes, beautiful appearance, corrosion resistance, not being easy to deform, and good heat dissipation performance, but aluminum alloy wheels are more prone to breakage than steel wheels, and their service life is slightly shorter than that of steel wheels. Aluminum alloy wheels are now mainly used in mid-to-high-end models of passenger cars.

In order to better compare the two, we chose 8 dimensions such as "appearance, weight/fuel saving, hardness, impact resistance, corrosion resistance, thermal conductivity, life, and cost" for a large PK:

1. Appearance: Due to the limitation of production, general steel wheels are monotonous and rigid in form and lack changes; aluminum alloy wheels have various designs, and the effects of luster and color also enhance the noble sense of value and beauty of the car. This is also one of the biggest reasons why aluminum alloy wheels are growing, so in terms of appearance, aluminum alloy wheels win!

2. Weight/fuel saving: The average aluminum alloy wheel is 2 kg lighter than the steel ring, and 5 pieces per car can save about 10 kg of weight. According to a Japanese experiment, every 1 kg of weight reduction of a car can save 12 liters of gasoline a year, and it can run 600-800 meters more under the same fuel consumption. In addition, a research report published by the American Society of Automotive Engineers pointed out that although aluminum alloy wheels are more expensive than ordinary steel wheels, when each car runs 20,000 kilometers, the fuel cost saved is enough to cover the cost, so in In terms of weight/fuel efficiency, aluminum alloy wheels win!

3. Hardness: The aluminum alloy wheel has high hardness, good roundness, and is not suitable for deformation. The wear of each part of the car is small, and it is suitable for high-speed driving; the steel wheel is soft and easy to deform. When driving at high speed, the car will obviously vibrate, which will affect the life of the car. , so in terms of hardness, aluminum alloy wheels win!

4. Impact resistance: Aluminum alloy hubs are harder than steel hubs, so under the same strength, the energy absorption is not as good as steel hubs, and it is more likely to break; while steel hubs have good elasticity and are more resistant to impact, which is also a lot The most important reason for American police cars to choose steel wheels, so in terms of impact resistance, steel wheels win!

5. Corrosion resistance: Due to the characteristics of the material, aluminum alloy wheels are more resistant to corrosion, while steel wheels are more prone to rust. Therefore, in terms of corrosion resistance, aluminum alloy wheels are better!

6. Thermal conductivity: The heat dissipation coefficient of the aluminum alloy wheel is two to three times that of the ordinary steel wheel. Coupled with the structural characteristics of the aluminum alloy wheel, it is easy to dissipate the heat generated by the tire and braking system into the air. In the case of continuous braking during long driving, the wheel system can also maintain the proper temperature. Aluminum alloy wheels can not only reduce the aging of the brake system and wheels, but also reduce the probability of tire blowout, thereby improving the safety of driving. Therefore, in terms of thermal conductivity, aluminum alloy wheels are better!

7. Life service: Due to metal fatigue aging and other reasons, the life of aluminum alloy wheels is slightly shorter than that of steel wheels, so in terms of service life, steel wheels are better!

8. Cost: The price of raw materials for steel wheels is relatively low, and the manufacturing process is relatively simple, so the cost is also lower. In terms of cost, steel wheels win!

To sum up, each car owner can choose the most suitable wheel hub according to different models and their actual needs.