Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

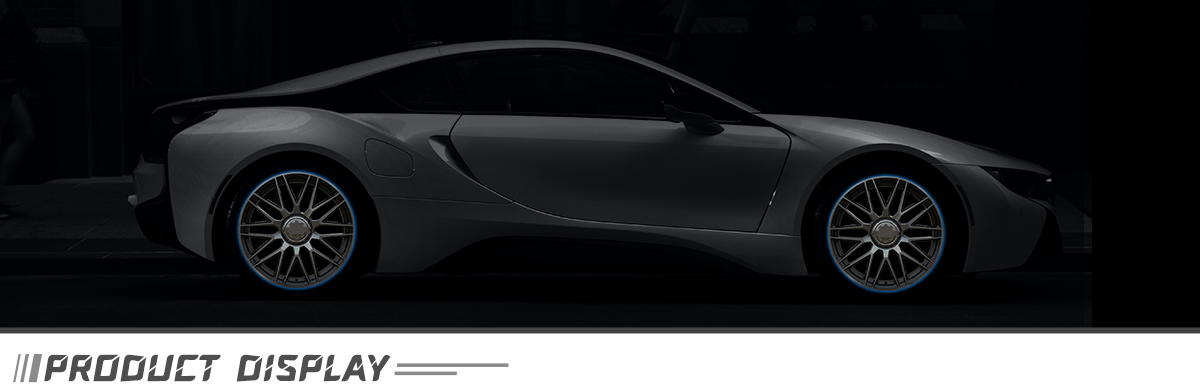

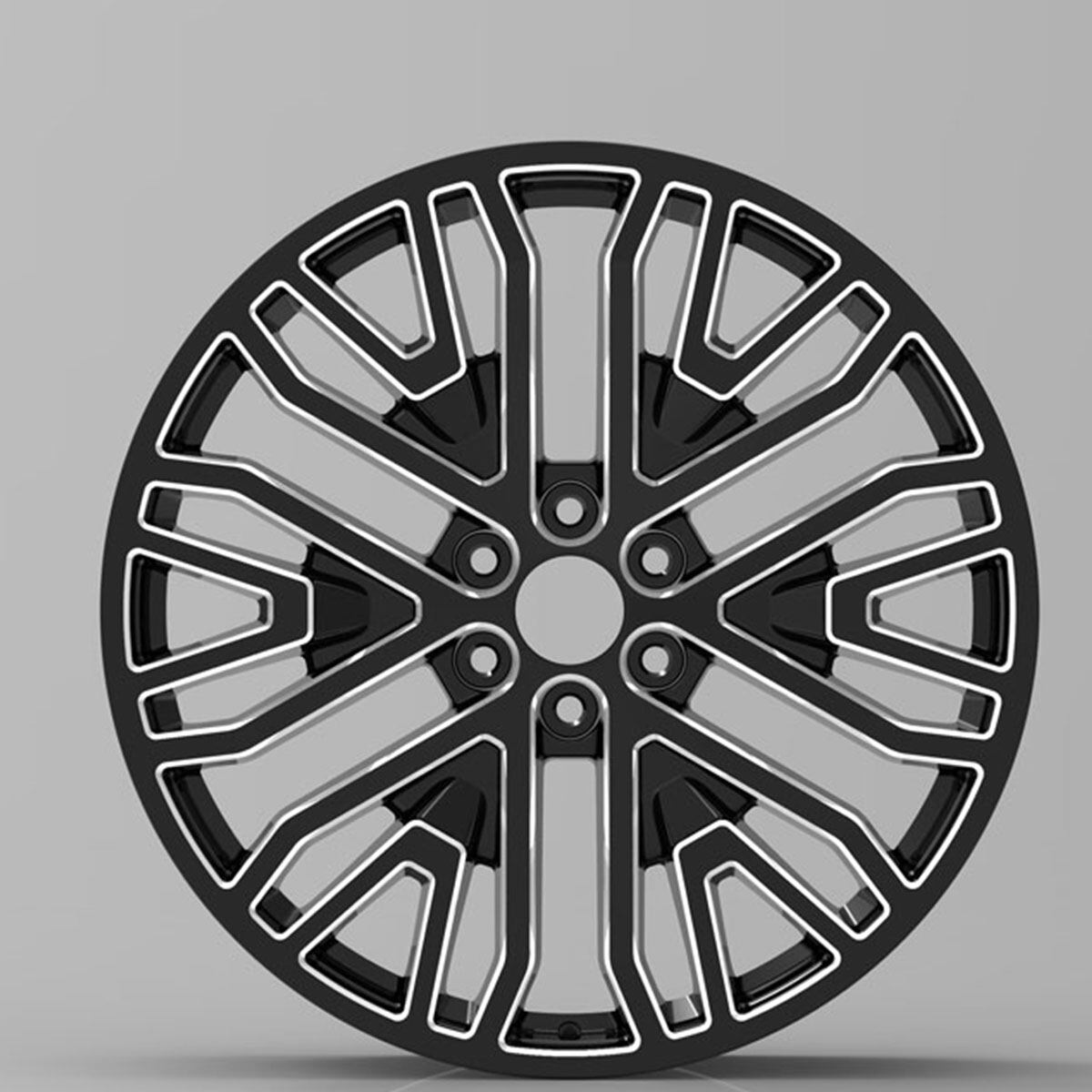

Black alloy 4x4 wheels - 2020 New Code 928

The aluminum alloy wheel reduces the weight of the car and improves fuel efficiency, but the longevity and strength of an aluminum alloy wheel are not as strong as the iron wheels. The main reason why people choose aluminum alloy wheels is because they love their stylish appearance.

The speed of a car is related to many factors, and the wheels are one of them. As we all know, iron wheels have been used for many years in low-profile models; this kind of wheel can also be used for daily use. However, there is a certain gap between the controllability and aesthetics and aluminum alloy wheels. It can also be said that not all people can accept these two points.

FITMENT SIZE ET PCD CB

METHOD 1680 0 5*127-150/6*135-139.7/8*165 77.8-124

METHOD 1785 0 5*127-150/6*135-139.7/8*165 77.8-124

Black alloy 4x4 wheels - 2020 New Code 928 is specially designed for sports cars and hatchbacks, which is much lighter in weight than steel wheels, but the strength of an aluminum wheel is not as high as that of a steel wheel. With its lightweight and strong structure , it can reduce fuel consumption by 10%

Features

The wheel weight reduction and fuel saving are the main reasons why people like to use aluminum alloy wheels.

Advantages

The wheel performance is not as strong as iron wheels, but it is more suitable for daily use.

It's much lighter in weight than steel wheels, but the strength of an aluminum wheel is not as high as that of a steel wheel. Aluminum alloy wheels are also durable and light, so you can use them for a long time.

Benefits

It is an excellent choice for sports cars and hatchbacks.

The appearance of the car will be sleek, and it will have a good anti-theft effect.

Advantages and disadvantages of aluminum alloy wheels

There are also some disadvantages.

The first is that it is too hard, so the toughness is not good. Although alloy wheels are more crash-resistant than steel wheels, they are a bit more brittle if they are too stiff. If it cannot withstand the impact, the aluminum alloy wheel is not deformed, but directly shattered. This steel wheel is slightly better. If the deformation is not serious, the airtightness of the tire can still be maintained, and it can still be used.

The second is the high cost, so it is also used for configuration classification by some cars. Now aluminum alloy wheels have different prices according to different manufacturing processes.

At present, there are several manufacturing processes for aluminum alloy wheels, namely casting and forging. Casting can be divided into two types. The first is gravity casting, which is simply pouring the aluminum alloy solution into the mold, and then polish and spray it after it is left to stand for molding. The second is pressure casting. In pressure casting, based on gravity casting, pressure is applied to the aluminum alloy solution in the mold, and it can be polished and sprayed after molding. Pressure casting is the casting method used by most manufacturers.

Forging is more advanced. Based on pressure casting, the aluminum alloy embryo is directly forged with a forging press. Because the pressure is controllable, different grades of hubs can be manufactured according to requirements.

Wheels manufactured by different processes have different prices. From high to low, the price can be divided into high-end forging > low-end forging ≧ high-end pressure casting > low-end pressure casting > gravity casting.

If the money is not bad, it is recommended to replace the iron wheels with aluminum alloy wheels

It is safe to say that iron wheels can be used. Since it has passed the factory quality inspection, even if it is an iron wheel, the quality is no problem.

Why does replace iron wheels with aluminium alloy wheels?

However, if the money is not bad, it is still a big improvement to replace the iron wheels with aluminum alloy wheels.

The first is that the weight can be lighter. Aluminum alloy wheels are basically 1/3 lighter than iron wheels of the same size. Probably a few kilos lighter. Although a few kilograms doesn't sound like much, if the four hubs add up, it's tens of kilograms.

The lighter the wheel hub, the lighter the unsprung mass of the vehicle. The so-called unsprung mass refers to the part that can still be placed firmly on the ground after the spring and shock absorber are removed. After this part is lighter, there is a saying called "1 kg unsprung, 10 kg on sprung". After the unsprung mass is lighter, the vehicle will accelerate faster, the performance of shock filtering will be better, it can also improve the cornering performance and handling of the vehicle, and also optimize the fuel consumption of the vehicle.

The second is to be able to deal with some extreme situations. After all, the hardness of the aluminum alloy wheel is higher. If it is really accidentally knocked, it will probably still hold up. Relatively speaking, iron wheels are weak in impact resistance and weak in response to extreme situations.

The third is better looking and more advanced. The steel wheels are basically black iron plates. At first glance, they are cheap goods, and even the car is also cheap. For many models, the low-end configuration is steel wheels, and the middle and high-end models become aluminum alloy wheels. If you spend a few hundred dollars, it can not only improve the appearance of the wheel hub, but also improve the grade of the model in disguise, which is more cost-effective.